Warehouse Management Functions

Stock transfer and putaway, picking and packing and inventory

audit are functions addressed by KP's warehouse management.

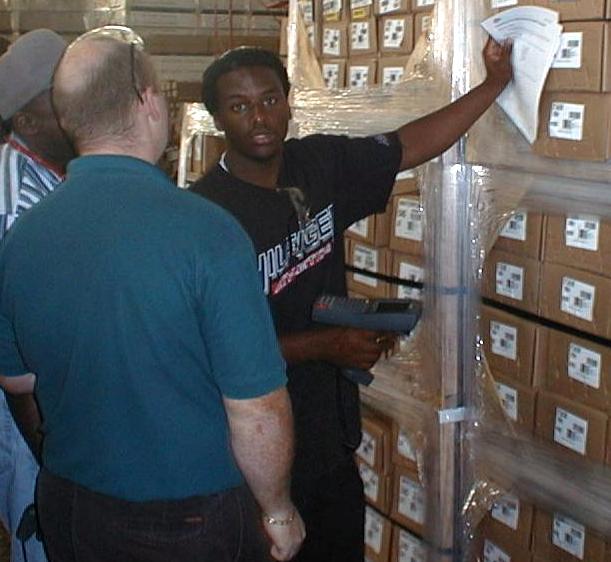

Stock Transfer

Stock must be transfered between locations and between storage

media, crates to cartons( on racks) or cartons to pieces and inventory must be adjusted

accordingly. The Stock Transfer module of the WISL Warehouse Management system utilizes

hand held RF based terminals networked to a Windows logistics server to handle this record

keeping.

Inventory Audit

Financial audits and periodic cycle counts are required to monitor

inventory. The Inventory Control module of the WISL Warehouse Management system provides

for inventory audits utilizing hand held RF based terminals. The counts are reconciled

with current counts in KP's corporate financial information system and facilities are

provided to monitor warehouse utilization and batch level product tracking.

WISL Warehouse Management

Initial inventory records are captured from WISL Process

Management through the Stock Transfer module. Stock transfer and picking and packing

interactive routines running on RF based terminals update inventory and provide

productivity data. The interface with WISL Distribution Control is via the picking/packing

interactive facilities.