|

| |

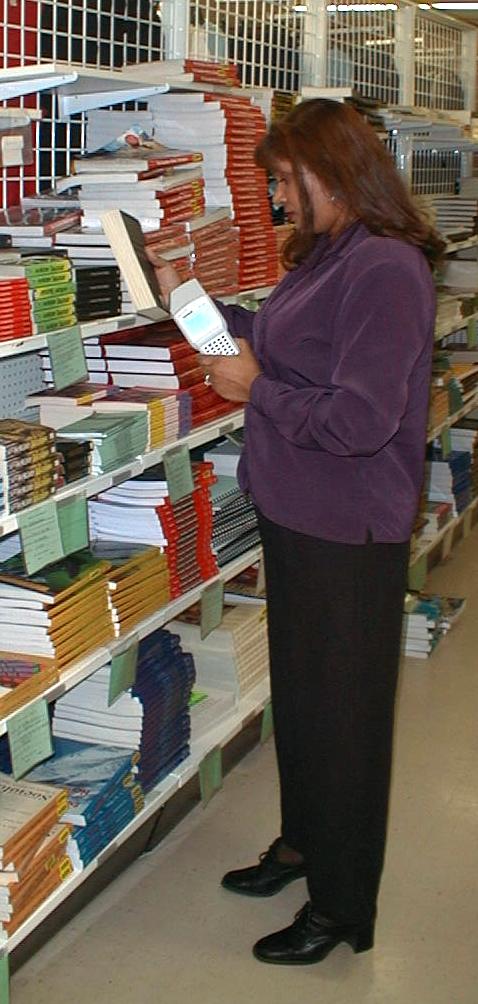

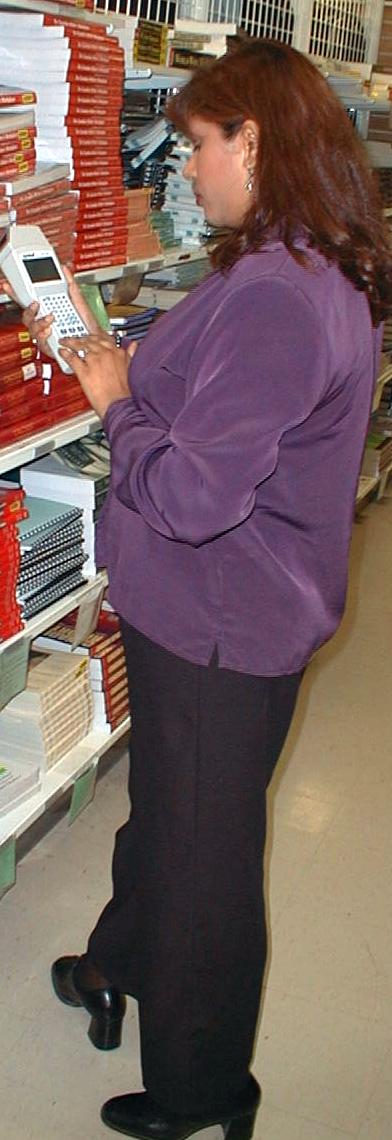

Inventory Maintenance includes facilities that

provide for periodic inventory audits. The audits can be performed as cycle counts or full

financial audits.

|

Upon initiation of the inventory audit

routine the operator is prompted for operator ID, the store(or warehouse) ID and the

destination store( or warehouse) ID. The repetitive activity of the inventory audit

function involves scanning the item UPC barcode then entering the item count. Upon

completion the scanner is placed in the cradle and the procedure is initiated to upload

the inventory transactions to the server. Reports are generated and the transactions are

applied to update inventory. |

|

WISL Inventory Maintenance offers the capability

to optimize the use of warehouse facilities. Stock transfer routines track product from

the warehouse to the store or between stores. Handheld data collection devices employing

barcode technology are utilized to control inventory activities.

|

Upon initiation of the stock transfer

routine the operator is prompted for operator ID, the source store(or warehouse) ID and

the destination store( or warehouse) ID. In the repetitive activity of the stock transfer

procedure the stock ID usually a UPC barcode is scanned from the item and the number

to be transferred is then entered. Upon completion the scanner is placed in the cradle and

the procedure is initiated to upload the stock transfer transactions to the server.

Reports are generated and the transactions are applied to update inventory. |

|

In the case of both stock transfers and

inventory audits, transactions are stored in handheld scanning terminals and up-loaded

through a PC workstation to the inventory management system. WISL IM provides for

reporting on the inventory transactional data and integration with the inventory

management system.

| |

|